Modern manufacturing can involve the use of different machines and technologies, but not every pairing will be productive for the task at hand.

Conversely, there are many technologies that work well together—so well, in fact, that one could believe the technologies were designed with each other in mind.

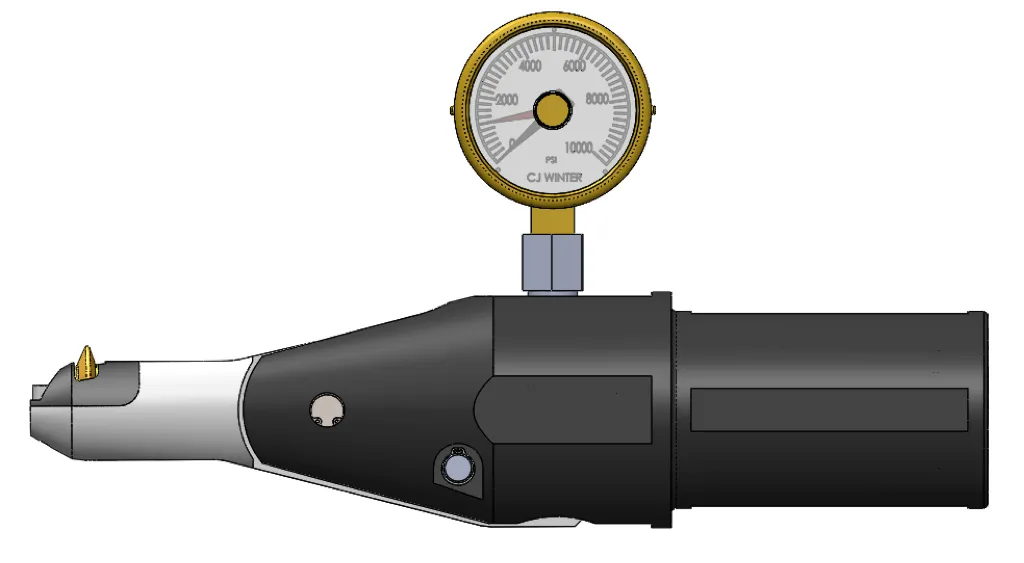

Cold Root Rolling (CRR) is becoming a more widely used industrial process due to its high success rate and adaptability to different equipment. CJ Winter’s CRR Tool is a self-contained tooling system well-known in the industry for its versatility. This tool can easily integrate with diverse machines, even those that use EIA standard Fanuc style G-codes.

Fanuc America has been a leading figure in CNC controls since the 1970s. G-codes—programmable commands used by manufacturing machines—have been standardized for over 30 years, but remain close to the Fanuc style structure.

Depending on the application, G-codes can provide several layers of control when integrated with our CRR Tool. CJ Winter’s new “How It Works” guide, Cold Root Rolling with Fanuc and G-Code, provides insight on this mutually beneficial integration.

What You’ll Learn From this Guide

This guide will touch on the history of the G-code programming language and explain the Fanuc style G-codes used to control CNC machines. You will learn about these automated style G-codes and the situations they are utilized in:

- Thread Cycle (G32) – Basic command for controlling feed rate and synchronization of the tooling

- Threading Canned Cycle (G76) – Used for running various command blocks in a single structure

- Threading Cycle (G92) – Canned cycle command for controlling the depth of each threading pass

Cold Root Rolling

with Fanuc and G-Code

For more information on CJ Winter’s CRR Tool and its capabilities with Fanuc-controlled CNC machines, obtain a copy of this guide or contact us today.