To adapt to the varying needs of their customers, industrial manufacturers have learned the benefits of utilizing different technologies.

Though the performance capabilities of machines—such as lathes—are important to specific applications, these machines should also be adaptable to newer tools and processes available.

With 40 years of experience providing manufacturers with innovative solutions, the Mazak Corporation has embraced the use of brand integration. Their line of CNC lathes offer users high efficiency and the versatility to utilize various accessories, including the Cold Root Rolling (CRR) Tool provided by the specialists at CJWinter.

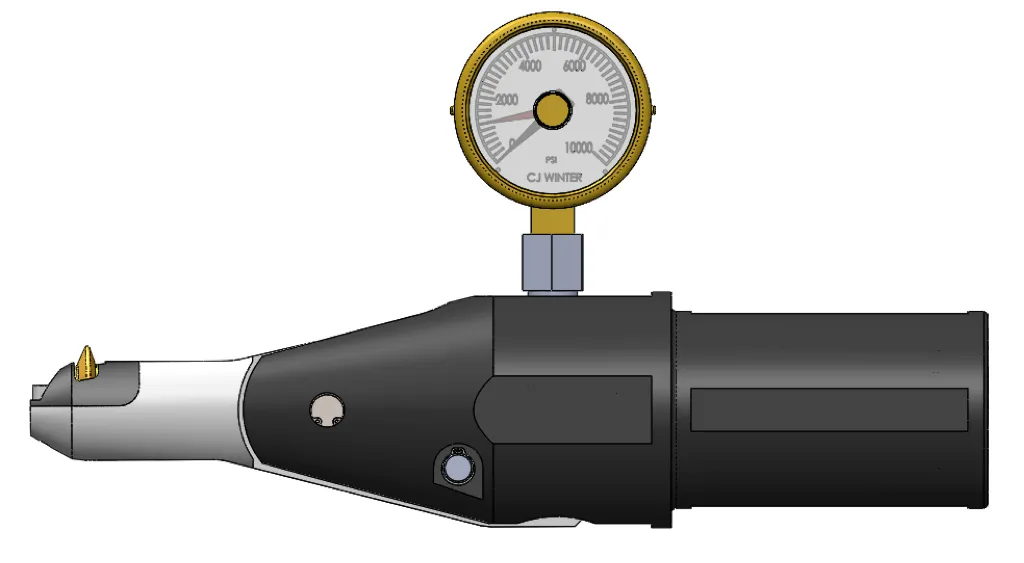

The CJWinter CRR Tool is a self-contained tooling system used to improve the surface finish of thread material, which results in an extended fatigue life of the threads. The CRR Tool can be integrated with minimal effort. Also, the tool will not damage the lathe’s CNC head—a distinct advantage of using Mazak machinery.

CJWinter would like to offer our “How It Works” guide, Cold Root Rolling with Mazak, to teach you how well these products integrate.

What You’ll Gain From this Guide

This resource will discuss the industry-proven CRR process in greater detail while elaborating on the lathe’s unique control system.

Mazatrol, the proprietary programming language used to control these lathes, has process codes that help support the CRR Tool. In turn, the CRR Tool helps simplify the process by requiring users to enter a few thread characteristics into the controller.

To learn more about the collaborative process between CJWinter’s CRR Tool and Mazak’s CNC lathes, obtain a copy of this guide today or contact us for more information.